Have an axle with an unknown ratio that you’d like to identify? Want accurate results? Here’s a simple, dead accurate method that will give you results on any rear wheel drive axle (or any front axle for a four wheel drive), as long as the axle in question is driven by a driveshaft. Sorry, front wheel drive folks, you’re generally out of luck on this one. This is a single-person technique. Helpers are not required, though one does make the counting a bit quicker.

Tools required:

Chalk, crayon, or paint pen

Jack

Jack stands

Safety:

I make the general assumption that you already know to follow all the necessary safety techniques. If you don’t already know how to do anything required here safely, find a friend to learn from, or another source of knowledge. General work safety practices for cars abound on the internet. Hence, work at your own risk.

Steps:

1. Determine if you have an open differential, or a traction aid (limited slip, locker, etc.). If you don’t already know, here’s how. Jack up the axle and put both sides on stands, so both wheels are off the ground. Leave the transmission in park or in gear (manual). Rotate one wheel by hand, while watching the opposite wheel. If the other wheel rotates easily in the opposite direction, you have an open differential. If there is resistance to rotation or no rotation, you have a LSD or locker. To verify a traction aid, place the transmission in neutral, and both wheels should rotate together when you turn one by hand. I’ll note differences in later steps between open and traction aid techniques.

2. LSD/Locker: leave the car on the stands. Open diff: lower one tire to the ground, leave the other on a stand.

3. Mark the tire and driveshaft. Put one mark on the tire sidewall where you can easily see it, and another on the driveshaft near the axle. You’ll need to be able to see both from where you’re working unless you have a helper, so they should both start out facing you. If you have a lot of tire clearance to your fenders, it’s often easiest to start with the marked spot toward the ground, and a block of wood or rock to use as a reference point. You want to be able to count tire turns to within a few inches of your starting point; more accurate than that won’t really be necessary.

4. Now, you’ll need to rotate the tire while counting turns of the driveshaft using your mark. Rotating forward or backward doesn’t matter. Turn the tire 10 turns for an LSD/Locker, 20 turns for an open differential. When finishing, try to count your last driveshaft turn to the nearest 1/4 revolution.

5. Divide the number of driveshaft turns you counted by 10 (same for both LSD/Locker and open). That’s your gear ratio.

Examples:

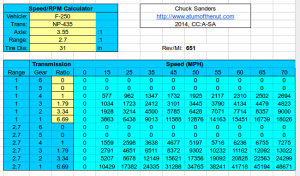

- You determine your pickup has an open diff, so lower one tire to the ground. You turn the tire 20 turns, and count 35-1/2 turns of the driveshaft. 35.5 / 10 is 3.55 – a common stock gear ratio for Ford pickups.

- Your car has a limited slip, so you leave both tires up. You turn the tires 10 times and count about 27-1/4 to 27-1/2 turns. This will be either 2.73 or 2.75 depending on your axle make and what ratios are available.

The last number is always a bit of a fudge with this method, but always close enough, as you’ll basically never encounter a single axle make that has two different ratios available that are so close. You can always count on the first two numbers, such as 2.7x and 3.5x, being dead accurate, and that’s always close enough to identify the exact ratio once you know what axle family you have. For instance, with a Ford, the 2.7x example is going to be 2.73 if you have an 8.8″ or 7.5″ axle, or 2.75 if you have an 8″ or 9″ axle.

I’ve used this method many times over the years, since it’s dead on and works great whether the vehicle still has its stock gears or not; axle tags are only useful if no other previous owner decided to regear. I also take a crayon with me any time I’m headed to a junkyard or to purchase an axle, for the same reason.

Happy counting!