I thought I’d add in an update on the (hopefully) final resolution of last year’s 300 I6 distributor trouble. I had one more failure, not long after my last post, and it was a particularly inconvenient one.

On 6/13, the roll pin for the distributor gear fatigued. Thankfully, it didn’t completely shear, but it did lose a layer on both ends, which means I lost about 20* of timing and all power. Unfortunately, it did this at 70mph, on a 95*F day, in the left lane, passing a semi on the interstate while pulling a loaded stock trailer, with a truckload of our good working dogs, 130 miles from home. I can think of less pleasant breakdowns, but not too many. This represents about 2,000 miles at most on this particular distributor install.

Thankfully, we were only twenty miles from a friend’s farm, and she came to our rescue. We left our rig and stock at her place overnight, and came back the next day with a couple of spare roll pins and enough tools to replace one roadside. We carefully limped everything home, and I started doing a postmortem.

My final conclusions on the problem came down to:

- Never re-use a roll pin in a distributor. The pin that sheared was the original pin from the Rich Porter. It may have been low quality to start with. Use an upgraded new pin every time you pull one out.

- You can’t get a properly made 300 I6 distributor, remanufactured or aftermarket. You’re going to need to do some careful re-engineering to reliably use any replacement you get.

- For the love of all that is holy, if you have a factory distributor that isn’t absolutely FUBAR, don’t replace it! I’ve never, ever personally had a distributor failure on a Ford that still had it’s factory distributor and where no one has screwed with it. Maintain or repair as needed, but any replacement you get is likely to be worse than the broken unit you’re pulling. I have no idea why the original part was swapped out on this engine before I bought it, but I’d wager good money it was because someone was throwing money and parts at a problem that had nothing to do with the distributor.

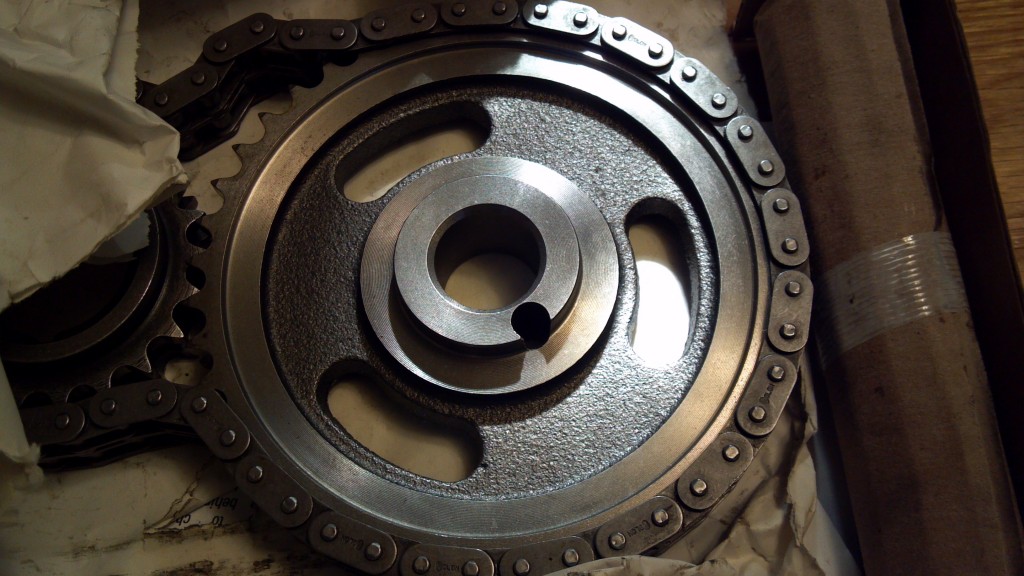

Here’s why your new or reman distributor is most likely to experience roll pin fatigue failures. The distributor gear should be a press fit on the shaft. That press fit should be what’s carrying all the load, and the pin should basically be a safety device.

However, the machining on new distributors is crap, and you can almost bet any reman you get will have had a failure which spun the gear on the shaft (my reman NAPA Echlin arrived that way). Either way, every distributor I’ve put in during this saga has had a distributor gear I could turn on the shaft by hand without the pin installed. The combo that fatigued on me was the loosest, and when you combine it with re-using the cheap pin that came from the RichPorter, you can see why it died. In fact, when I re-pinned the NAPA and drove it carefully home, the pin I popped in (which was the original NAPA pin) had already started to fail when I pulled it out that evening – under 150 miles.

My solution to this has so far worked for six months and about 10,000 miles. First, I bought a 100 pack of brand new, high strength roll pins. They are about 30% stronger than the standard roll pins of this size, and probably almost double the strength of the off brand pins that came with both the Rich Porter and the NAPA reman.

Second, I went ahead and bought a brand new Rich Porter, with the intention of immediately tearing it down. They are almost the only game in town in terms of new 300 I6 distributors, and if I’m going to start with junk either way, I’d rather it be new junk with a lifetime warranty. Upon arrival, I immediately pressed out the crappy stock pin, pulled the gear (which was loose, but a lot better than the NAPA unit started out), and removed enough end play shims to get the end play up to 0.030 where I wanted it. I really didn’t want a repeat performance of the original Rich Porter getting too tight and popping it’s hall plate off the top splines, since that was the only problem I actually had with the original Rich Porter.

After a careful break-in and timing set, that combo has now been in for about 10,000 miles, including plenty more miles on the interstate with the stock trailer. That means this has also lasted at least 6,000 miles more than any other distributor we’ve had in it since purchase last year.

I was also determined not to get stuck by a failure again if I could help it. I replaced the already fatiguing “new” pin in the NAPA with a new high strength one, and have that crap distributor and enough tools and spare pins to change and repair it roadside sitting in the van’s toolbox. I’ve got that routine down to about 20 minutes, which is a lot faster than the tow truck showed up. I just checked the pin by feel last Friday (the shaft movement feels “soft” when they’re starting to break), and so far it still feels good, with no measurable timing loss with the light either.

I’ve seriously considered selling these nice little pins as singles or small packs on eBay or Amazon. At $2 a pin plus the cost of a stamp and an envelope, they’re a lot cheaper than the 100 pack I had to buy, and cheaper than the single pins anyone else is selling online (mostly $5 and up). You can’t get them in quantities less than 100, and I hope to never use up the other 99. They’re high strength steel and have a minimum double shear break strength of 2,000lb, which means they are good for 44 ft-lb for the distributor gear in a 300 or 351W, or 39 ft-lb in a 302 (smaller shaft). I’ve got the info on them if anyone wants them, or would probably mail a few for a couple of bucks plus postage.

Here’s hoping this helps someone else out, too. I’ll update again if I ever get another failure with this. Meanwhile, I’ve seriously started considering getting my own shafts machined so I can actually get a proper fitment. Most likely I’ll probably end up swapping in the spare 302 I have instead, though. The 300 isn’t the best in the world right now with a stock trailer at 70.